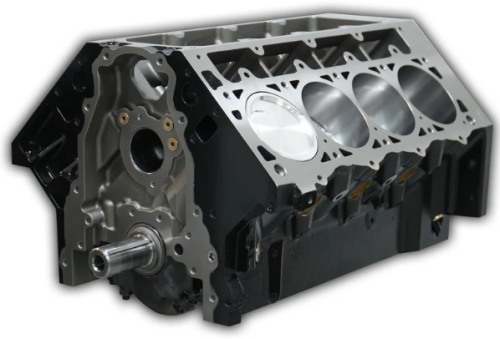

LME Dart SHP Pro 388" Block

<< Back

SKU

LME Dart SHP Pro 388" Block

As low as

$13,799.00

***Stock my vary, lead times can be up to 8-10 weeks. Please call or email sales@vengeanceracing.net for questions***

LME 388" DART SHP PRO Shortblock is a proven combination to get more cubic inches and power for your ride. This block will go into any LS-powered vehicle! Any LS1,LS2,LS3,LSA,LS7 or LS9 can be pulled out and replaced with this stout unit! This engine is set up for a forced induction application. Supercharger, turbos, procharger it doesn’t matter this engine will take it. The aluminum block saves weight for those applications in need of weight savings.

| Displacement: | 388" | Bore: | 4.125" |

| Proven Power Rating: | 1400/1800/2000+ HP | Stroke: | 3.625" |

| Compression Ratio: | 10.5:1 w/ 64cc Chamber | Rod Length | 6.125" |

| Cylinder Head Compatibility: | Any LS | Oil System Type: | Wet or Dry |

| Block: | DART SHP PRO |

| Crankshaft: | Callies 4340 Compstar 8 Counterweight w/ LME Blueprinting Process |

| Connecting Rods: | Callies Compstar XD (1600HP Rated)w/ARP Bolts |

| Pistons: | LME/Diamond 2K Custom Forged FI w/Gas Ports (.300" material above top ring land) |

| Wrist Pins: | Trend H-13 Tool Steel Heavy Wall .250" |

| Ring Pack: | Total Seal 1.5mm AP Stainless Top (for high heat applications) .043" Ductil Napier Second, 3mm Oil |

| Bearings: | Clevite H-Series Main & Rods |

| Main Studs: | ARP |

LME Standard Shortblock Blueprinting Process:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SKU | LME Dart SHP Pro 388" Block |

|---|